- Non-Structural Column Wraps

- Structural Fiberglass Columns

- Cellular PVC

- Decorative Millwork

- T&G | Shiplap Planks

- Premier Shutters

- Outdoor Living

- Ceiling Beams

- Flexible Mouldings

- Interior Ceilings & Walls

- Wainscoting

- Clearance Items

Tools Recommend To Install Cornice Mouldings

| Cornice Mouldings Instructions | Setting for Miter Saws |

Many people think that cornice is very difficult to install. Others think it is very simple because they saw the guy on T.V. do it in half an hour. The truth is cornice can be done by the do-it-yourself-er, with the right tools and a little bit of patience. Please be aware that this guide is meant for the first-time installer, so some of the terminology and things that come as second nature to professionals will be explained thoroughly. There are many schools of thought when it comes to installing cornice; this guide will teach you the method our installers use. It's not to say that the other ways are wrong but we find that this method works very well for us.

Many people think that cornice is very difficult to install. Others think it is very simple because they saw the guy on T.V. do it in half an hour. The truth is cornice can be done by the do-it-yourself-er, with the right tools and a little bit of patience. Please be aware that this guide is meant for the first-time installer, so some of the terminology and things that come as second nature to professionals will be explained thoroughly. There are many schools of thought when it comes to installing cornice; this guide will teach you the method our installers use. It's not to say that the other ways are wrong but we find that this method works very well for us.

One of the advantages of MDF mouldings, unlike plaster, is that the walls and furniture do not have to be covered or draped. If your house is under construction, the cutting can be done anywhere. If however, you are living in the house, we ALWAYS cut our wood outside, in the garage. The fine MDF dust would otherwise take days to completely vacuum out.

Cutting is done using a Compound Miter Saw with a 10-inch draw. The draw is the distance the saw arm can cut in one pull. Although the cornice comes in various widths up to 7 inches, the width of the cornice increases in direct correlation with the angle of the mitre.

Cutting is done using a Compound Miter Saw with a 10-inch draw. The draw is the distance the saw arm can cut in one pull. Although the cornice comes in various widths up to 7 inches, the width of the cornice increases in direct correlation with the angle of the mitre.

The difference between a compound and a normal mitre saw is that the compound allows you to make both a Bevel and a Miter cut at once. For best accuracy, cornice mouldings should always be cut flat not on a 45 degrees angle. Cornice requires two angled (compound) cuts because it is installed onto the wall and ceiling at a 45 or 52-degree angle. Unlike baseboards which are installed flat onto the wall and only require a single angle cut (or a mitre).

Measure as accurately as possible down to the closest 16th of an inch. Make sure you note the Inside and Outside Corners. To explain inside and outside corners, imagine a perfect square, if you are standing inside the square, you will only see inside corners. If you walk around the outside of the square all you will see is outside corners.

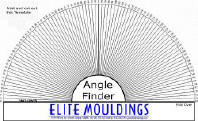

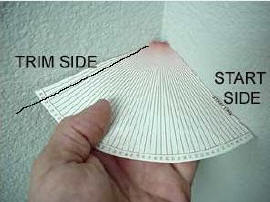

ANGLE FINDER

Before we begin cutting we must determine the correct angle using an Angle Finder. A perfect 90-degree angle should never be assumed, what looks like a 90-degree angle may be off slightly. If the two joining cornices are not a tight fit, the glue will not adhere well. Once the angle is determined use our Cutting Chart to set the compound mitre saw in order to get a nice tight corner.

Using the Angle Finder and our Cutting Chart you should be able to set the Bevel and Miter angles required to make the proper corner. We normally recommend that you make yourself small inside corner and outside corner samples before you begin cutting into the long lengths that will be installed.

Compound Miter Settings |  | ||

This should allow you to visualize what each corner will look like before cutting. Now that we've cut a few pieces, it's time to pin them up in place. We will require a Compressor and a Pneumatic Finishing Nail Gun, which works as such. The reason for the nail gun is simple when set properly; the nail gun automatically countersinks the nail heads about a 1/4 inch into the cornice. This allows for an easier time when finishing (we'll get to that later). We normally have the compressor set to between 98 and 110 psi. Installers, who have never worked with MDF before, should test and adjust the air pressure as needed for their specific equipment. We find that the best fasteners for the job are 15 - 18 gauge brad and pin nails approximately 1 1/2 to 2 inches in length. We apply a pair of nails on both the top and the bottom of the cornice every 12- 16 inches in an "X" pattern. The "X" ensures that even if a joist wasn't caught with a nail the cornice will not fall down because the "X" creates a fastener in the drywall.

This should allow you to visualize what each corner will look like before cutting. Now that we've cut a few pieces, it's time to pin them up in place. We will require a Compressor and a Pneumatic Finishing Nail Gun, which works as such. The reason for the nail gun is simple when set properly; the nail gun automatically countersinks the nail heads about a 1/4 inch into the cornice. This allows for an easier time when finishing (we'll get to that later). We normally have the compressor set to between 98 and 110 psi. Installers, who have never worked with MDF before, should test and adjust the air pressure as needed for their specific equipment. We find that the best fasteners for the job are 15 - 18 gauge brad and pin nails approximately 1 1/2 to 2 inches in length. We apply a pair of nails on both the top and the bottom of the cornice every 12- 16 inches in an "X" pattern. The "X" ensures that even if a joist wasn't caught with a nail the cornice will not fall down because the "X" creates a fastener in the drywall.

The placement of the nail on the face of the cornice plays an important part in the installation. If you look at the back of the cornice, you will notice that there are three flat sides to it. The two small angles are the parts that touch the wall and the ceiling. These two angles run along the entire length of the cornice and these are the two areas you should be aiming for when you begin nailing. You should always try to place the nail gun so that the nail head is hidden into a crease on the face of the cornice. Although the nail head is countersunk, the hole is visible sometimes even after we cover it and sand it, whereas, in a crease, it disappears.

All corners should be glued using MDF Glue or MitreBond which can be picked up at any of the large box stores. We don't use either white or yellow woodworking glue because both of these glues remain slightly flexible, even when they are fully cured. That means that in time they will allow the MDF. MDF wood fibres to slip a bit. Manufacturers call this "creep". The solution is to use glues that will cure rock hard. Another thing to consider is that MDF is far more fibrous than solid wood and so using water-based glues will cause "swelling" at the joints. MitreBond is a very thin solvent-based glue that results in a virtually invisible seam.