MDF vs PVC for Mouldings

Today let’s talk about materials, specifically MDF and PVC. One is mainly for the interior and the other for the exterior but in this post, we’re going to talk about why. We’re looking at the components of each material, the pros and cons, as well as what they are used for.

Let’s start with MDF.

MDF stands for Medium Density Fiberboard. It is a type of fiberboard made from wood or other lignocellulosic (aka dry plant matter) materials that are refined into fibres and reconstituted with a resin binder (glue) at high temperatures. It is one of the four main categories of wood-based panels which also include laminated boards, particle boards, and oriented strand boards.

The reason that MDF is so popular as a material is that it’s easier to machine than natural wood and it can be laminated and painted to create almost any board finish. It also has a lot of characteristics similar to natural wood and so can be used as a substitute for it.

So why MDF? Well, the components in it make it resistant to warping, moisture, and compression, which makes it a great choice for your home or business. It can be used for wall or ceiling paneling, as well as trimwork, skins for flush doors, office screens, and more. It’s produced locally in North America and you can find more information at these manufacturers: Uniboard, Arauco, and West Fraser.

The downside to MDF is that it’s not the best choice for the outdoors. That brings us to PVC.

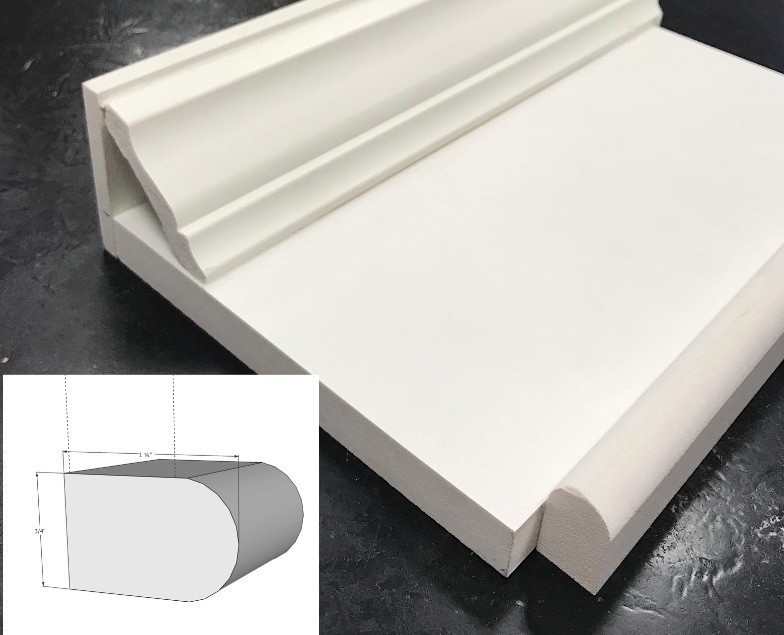

PVC stands for polyvinyl chloride compound.

It is one of the most widely produced plastic polymers in the world. The process for making PVC is interesting because the main components are saltwater and ethylene from oil. It results in high-density plastic. PVC comes in two forms, rigid and flexible. The rigid PVC has the highest density out of the two which results in the material being very strong and hard. That’s not to say the flexible isn’t strong as well, but it doesn’t have the same density as the rigid form does. It can have the look of cedar and other woodworking characteristics.

So why PVC?

Well, because it is a plastic polymer, it’s moisture and insect-resistant. That makes it ideal for areas that deal with a lot of moisture, such as a house on the coast, or a location that deals with high humidity. It does not require painting and can be used in direct contact with masonry.

As you can see, there are quite a few differences between the two of them. Because of their properties, MDF is best suited for internal applications whereas PVC is best suited for external ones. Both of them provide a wonderful addition to any home or business, allowing you to create a look that suits you.

Be sure to check out our posts on crown moulding part 1 and part 2!

Also check out our post on exterior trimwork!