- Non-Structural Column Wraps

- Structural Fiberglass Columns

- Cellular PVC

- Decorative Millwork

- T&G | Shiplap Planks

- Premier Shutters

- Outdoor Living

- Ceiling Beams

- Flexible Mouldings

- Interior Ceilings & Walls

- Wainscoting

- Clearance Items

Making Engineered Beams for Pergolas

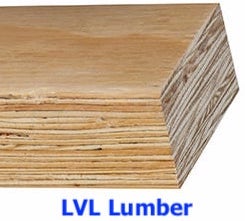

As Cellular PCV is purely decorative, anytime a component of your outdoor structural is required to carry weight, some type of structural beam is required. Most of the time, we include a 1" x 3" aluminum tube to be our PVC Rafters from sagging. For bigger support beams that carry heavy loads, we suggest LVL (Laminated veneer lumber), any lumber to be installed first, then clad with decorative white, PVC. PVC is maintenance-free and will not rot, split or crack the way that wood does.

Many contractors that work on large construction projects prefer to use LVL (Laminated veneer lumber) for framing. For its size, LVL is stronger, more stable and will not warp the way traditional lumber does. When structural beams for outdoor structures or pergolas are required, engineered beams get the job done. Pergola beams carry a relatively light load and are much easier to make than they are to find in the right size at your local lumber yard. Both LVL and Engineered Beams are equally effective.

Many contractors that work on large construction projects prefer to use LVL (Laminated veneer lumber) for framing. For its size, LVL is stronger, more stable and will not warp the way traditional lumber does. When structural beams for outdoor structures or pergolas are required, engineered beams get the job done. Pergola beams carry a relatively light load and are much easier to make than they are to find in the right size at your local lumber yard. Both LVL and Engineered Beams are equally effective.

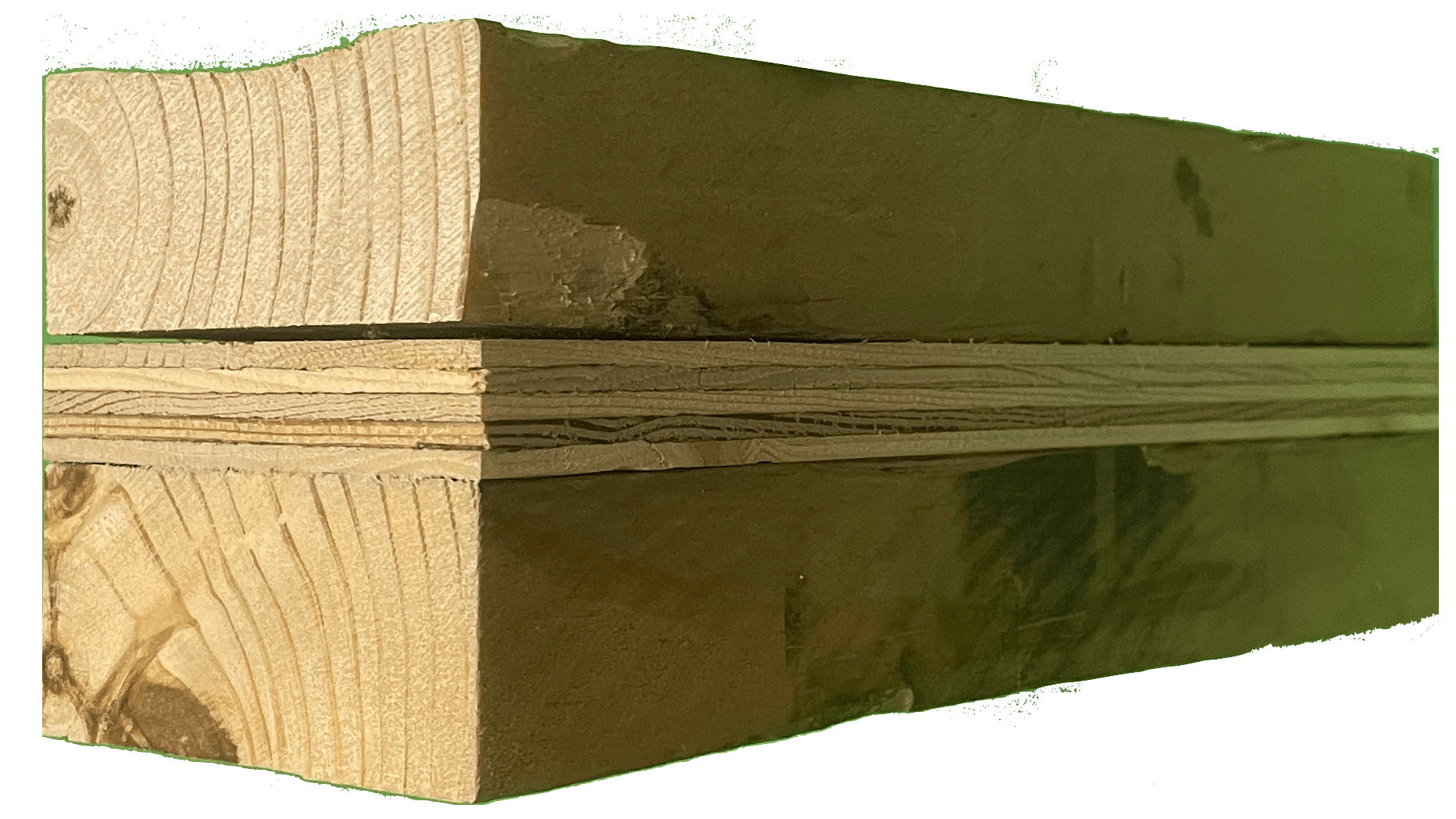

Engineered Beams can easily be made on the job site in less than an hour. Pressure-treated wood is recommended for outdoor applications.

Engineered Beams can easily be made on the job site in less than an hour. Pressure-treated wood is recommended for outdoor applications.

For the lighter loads and shorter spans that are typically used for Pergolas, homemade, Engineered Beams are very practical. Depending on the load requirement, we suggest using two 2x4 or 2x6.

To keep the beam stable and from twisting, add a layer of plywood or aspenite in between. Add construction adhesive like PL Premium between the layers. Next, fasten with coarse threaded Timber Screws and you're done! The Aspenite or plywood in between will keep the beam from sagging or twisting.

If unsure, ask the staff at the lumberyard for advice on sizing.