- Non-Structural Column Wraps

- Structural Fiberglass Columns

- Cellular PVC

- Decorative Millwork

- T&G | Shiplap Planks

- Premier Shutters

- Outdoor Living

- Ceiling Beams

- Flexible Mouldings

- Interior Ceilings & Walls

- Wainscoting

- Clearance Items

Installing Large PVC Wraps

Installing Large PVC Column Wraps

Want to print these instructions? Download a PDF version here.

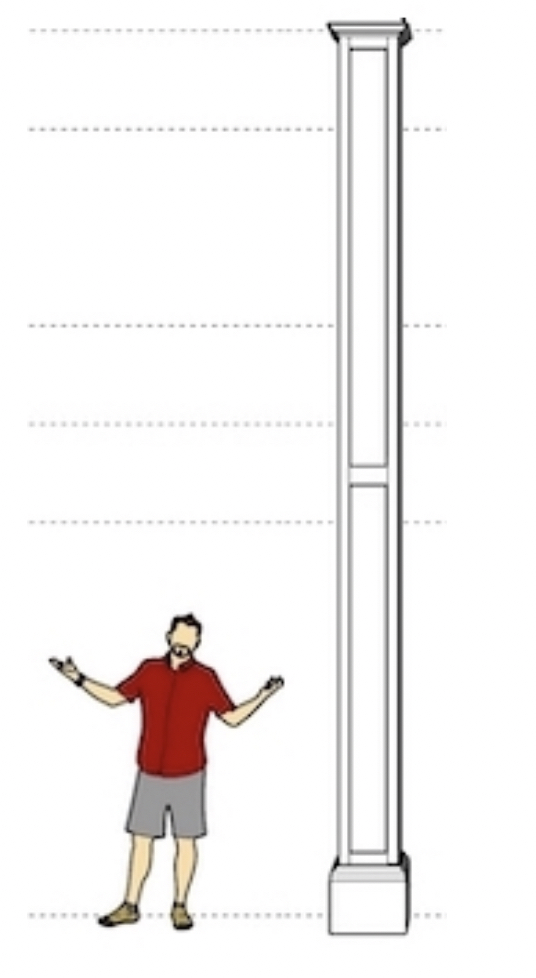

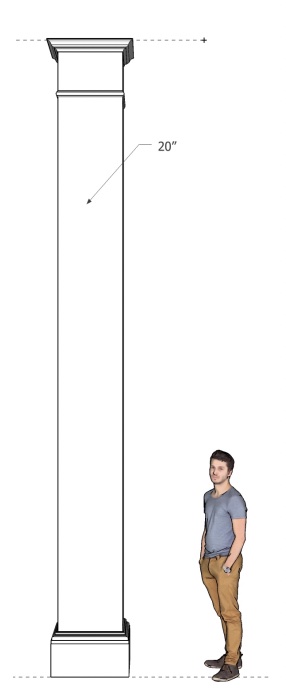

Congratulations on your purchase of Elite Trimworks Premium PVC Columns. To get the best results, we recommend that you, or your contractor, read the following installation tips prior to starting the installation. Please note these tips are meant for Column Wraps that are over 12” wide and are over 12ft tall. Taller columns usually require at least two people to install them.

Before cutting any panels, please keep in mind depending on the length of the columns, in some cases, we ship the capital and/or base in separate sections to reduce shipping costs. Please ensure you inspect all parts sent with your order, to determine whether you have a 1, 2, or 3 section column shaft. The extension parts will be clearly labelled.

A Special Note for Recessed Panelled Columns: Columns 12ft tall, or less, will be shipped with a middle divider rail taped in place, which can easily be adjusted/removed. Taller Recessed Panelled Columns (over 12ft) have this divider glued in place at the centre of the shaft, to cover any seams. If you decide to cut the shaft down, ensure you cut equal amounts from both the top AND the bottom of the column, to keep your panel sizing equal. The divider at the top and bottom of the shaft are taped in place and can be adjusted to your preference. Glue the dividers in place as a final step (Use the tape to hold the dividers in place while the glue dries). We recommend positioning the dividers leaving about 3” exposed once the Cap/Base are applied, as this is the ideal format to match with the rest of the exposed panelling along the shaft corners.

1. Measure the height of where the column is to be installed. Reduce this measurement by about 1" and then cut the column panels (cut before assembling the shaft).

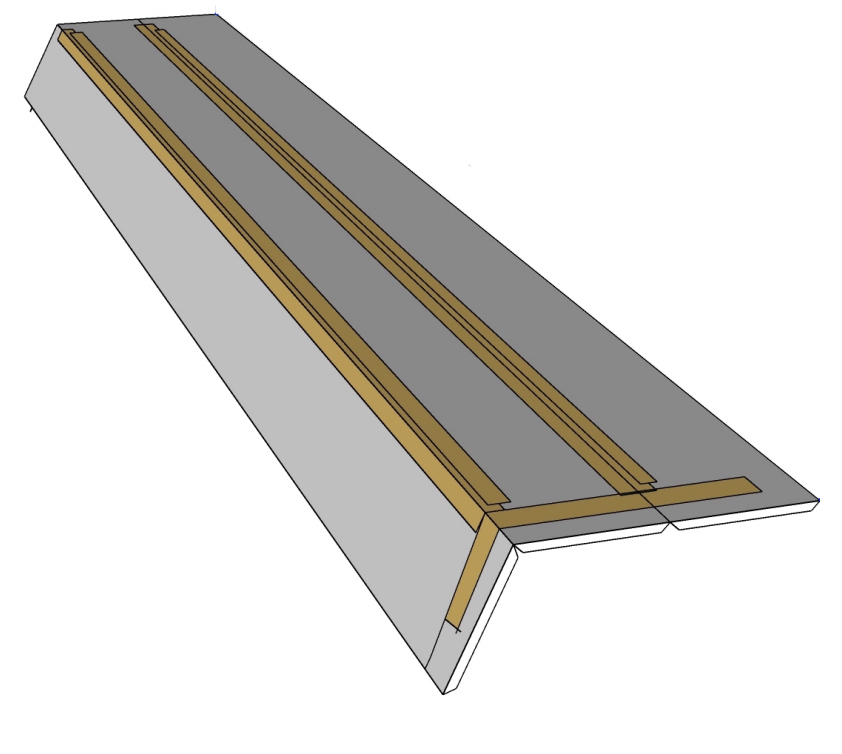

2. Tape three column panels together as shown on page 2, and make sure that the lock mitre edges line up with each other. Next, flip them over, apply adhesive to the 90 degree/lock mitre joints, and fold them into a “ U” shape. The alternative is to assemble two "L" shaped pieces onto the shaft. This is called the "book tape method”, which makes a very tight seal and results in a strong bond.

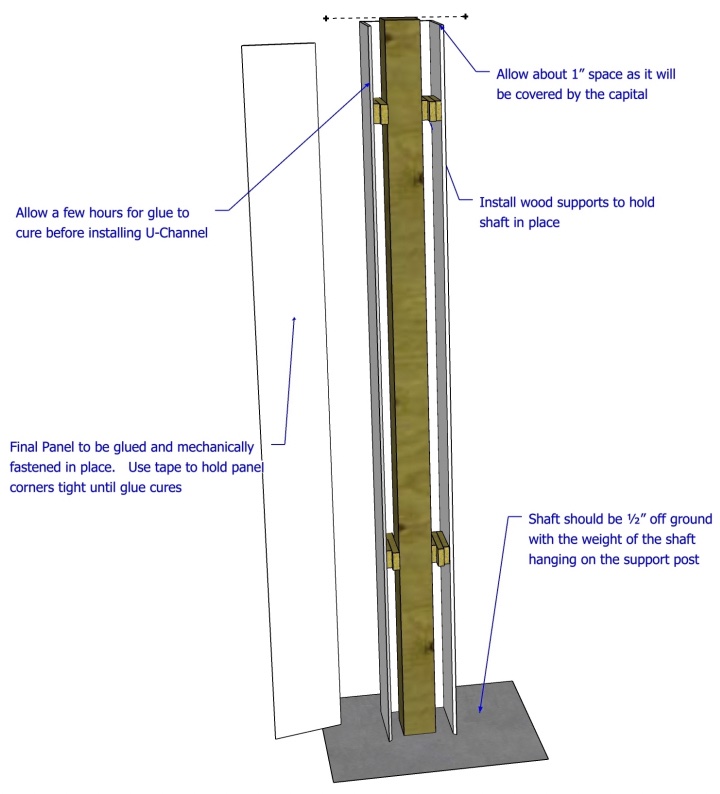

3. Build a support frame / blocking around your existing support post, about ½” smaller than the INSIDE of your column shaft. You can use shims to do the fine adjustments to perfectly position your column. Depending on the height, you may want 3 or 4 of them; we recommend spacing these about every 6ft. Use a level to make sure that the panels are square, before fastening in place. Using the Tapcon screws (provided), screw the PVC cleats (provided) into the floor/concrete. For the top and mid sections, use Pressure Treated Lumber for the blocking.

4. Place the partially built shaft in the desired position and level (plumb). Add shims between your framing/ blocking and the wrap to secure, then drive screws (not provided; we recommend using coarse threaded screws that are corrosion-resistant), from the outside of the shaft into the frame. Ideally, drive the screws in the portions of the shaft that will later be covered by the capital and the base trims. Additional screws may be required based on overall height and support framing used.

5. You will screw into the face of the shaft where you installed the framing/blocking. We do not recommend using a nail gun as it will not hold tight.

6. You are now ready to glue and tape in the last panel. Drive small screws on the corners of the column for additional strength. Once the glue has set, remove the tape and pin (brad nail), or screw the cap and base in place. In the event that any of the corners open up, lightly sand them down with sandpaper.

7. Fill any imperfections with exterior caulking or speckling; then sand lightly, wipe down/clean, and then you are ready to paint. Painting is not required on PVC but it does improve the overall appearance of the column.

TIPS & BEST PRACTICES

Please review these time-saving tips before you start installing your extra tall PVC columns. As these columns are longer and heavier than standard columns, there are a few things different about how they are installed.

- You will use larger PVC cleats or Pressure Treated Wood to mount the column. The shaft should have supports at six-foot intervals.

- Unlike shorter columns, these columns should be glued up into a “U” channel section first, then assembled around the post.

- When taping the three panels to form the “U”, use 3 strips of tape instead of one. We include extra tape for this purpose.

- Mechanically fasten (or pin), and tape all three of the column panels together first. We do not include the fasteners as the requirements vary from job to job. • Mechanically fasten (or pin), and tape the last panel section around the support post.

- The Glue we include only bonds PVC to PVC and takes 24 hours to fully cure. Do not remove the tape until it cures. 80% of the curing, occurs within the first 3 hours. • Do not leave the tape on too long after the glue cures, it may leave gum from the tape behind.

Safety: This is NOT to be intended to be taken as safety advice, see specific safety precautions in the owner’s manual of your power tools.

Handling: We suggest that you use gloves and great care in handling you're PVC parts. Unlike wood, edges on PVC can be razor-sharp.

Load-Bearing Capacity: PVC column wraps are purely decorative and have not been tested for load-bearing capacity. Railings: If there are railings to be installed, ensure the rails are secured to the structural support. Use only code-approved methods for installation. Use a metal bracket or pressure-treated lumber between the support post and the inside of the PVC wrap. Do not use untreated lumber for structural or railing support.

Cutting and Fastening: Cellular PVC can be cut, nailed, and fastened with the same tools that are used for wood (with minor differences). Avoid large power framing nailers and pre-drill for any screws larger than 1 ½”. Coarse threaded screws are best.

Cold Temperatures: Cellular PVC becomes brittle the colder it gets. Keep columns indoors prior to installation when working in cold temperatures. Avoid striking the face of the column with a hammer.

Painting: When cellular PVC columns are painted, you can not tell them apart from their wooden counterparts. Cellular PVC does not require painting for protection. Paint lasts much longer when applied to PVC versus adhering to wood due to the absence of internal moisture. If painting is preferred, follow these guidelines. Putty any holes using acrylic putty or caulking. Lightly sand or scuff surface of the column. Clean the surface of the column to remove any dirt or oil residue with light detergent and water, or window cleaner.

IMPORTANT - Use 100% acrylic exterior paint or acrylic with a light reflective value (LRV) equal to or greater than 55 units. Failure to follow this requirement will void our product warranty. Consult Sherwin Williams or Blue River Coating in applications where the paint colour has an LRV value less than 55 units.

Want to print these instructions? Download a PDF version here.