- Non-Structural Column Wraps

- Structural Fiberglass Columns

- Cellular PVC

- Decorative Millwork

- T&G | Shiplap Planks

- Premier Shutters

- Outdoor Living

- Ceiling Beams

- Flexible Mouldings

- Interior Ceilings & Walls

- Wainscoting

- Clearance Items

Installing CertaTrim Trimboards

CertaTrim® Installation Guidelines

From CertainTeed. Want to print a copy? Find the PDF here.

Safety

CertaTrim exterior trim is a cellular PVC product and cutting it will create PVC dust and particles.

- Cut cellular PVC trim in an open, well-ventilated area.

- Always wear safety glasses or goggles and a face mask when cutting CertaTrim.

- If you cut the trim with a power saw, wear a dust mask.

Storage and Handling

CertaTrim is more flexible than wood, so it may conform to uneven surfaces, particularly in warm weather.

- Store CertaTrim up off the ground on a flat, level surface. If the product is stored in a cantilever rack, use the CertainTeed shipping pallet to provide support.

- If trimboards get dirty, clean the trim with a soft bristle brush and mild soap and water before you install it. Use the pallet shroud or a tarp when storing the product outside.

- When moving and installing CertaTrim, handle it the same way you would handle soft pine lumber.

Cutting

You can cut CertaTrim with a conventional carbide-tipped blade that is designed for working with wood. Do not use fine-tooth metal-cutting blades. Do not use plywood or metal blades because the kerf of the blade is too thin and can cause heat buildup in the material. For best results, use a 32-tooth (or higher) blade designed for woodworking. To maintain a smooth edge, support the trim across its entire length when you cut it.

When it is cut properly, CertaTrim will have a smooth edge. If you get a rough edge from cutting, check for excessive friction, a worn saw blade, or badly aligned tools. Rasp and sand the trim to restore a smooth edge.

Drilling

You can drill CertaTrim with standard wood-working drill bits. Do not use bits made for rigid PVC. Avoid heat buildup from excessive friction, and remove the shavings from the drill hole frequently. To avoid injury, take precautions when using a hole saw.

Routing

For crisp, clean edges, use a sharp carbide-tipped bit on a router. For smooth milling, it is important to adjust the speed of the router and control the “push” rate. Hand-held routers are difficult to control, so we recommend that you mount the router on a table.

- Make sure the router guide bearing is running along a smooth cut.

- Go over the cut a second time to smooth out the router edge.

Finishing

Use machine edging, sanding, grinding, or filing to finish field-cut edges. To scuff sand CertaTrim trim, use 100–120 grit sandpaper or a Norton Abrasive Sponge. The finished edges will have the texture of the interior cell structure, which is a cosmetically smooth surface.

- Do not allow excessive heat to build up.

- For a smoother edge, spackle, sand, or paint the finished edge.

Expansion and Contraction

Vinyl building products expand and contract as the temperature changes. You must allow for this movement when you fasten CertaTrim. You can minimize the movement of PVC trim by observing proper fastening techniques along the entire length of the trim.

- Allow 1/4 in. per 18 ft. of product for expansion and contraction (1/8 in. at each end).

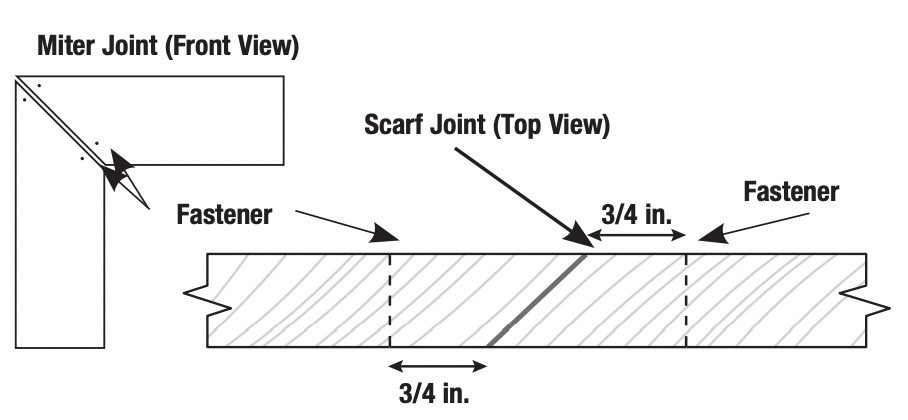

- 30° to 45° scarf joints work well to minimize seams and allow expansion and contraction.

- Glue scarf joints between the pieces to help control separation caused by expansion and contraction. (see "Bonding, Adhesives and Joinery" section for more on proper bonding techniques).

- Gluing the joints moves the expansion and contraction out to the ends, where movement is covered by CertaTrim onepiece corners. However, in some situations glued scarf joints can result in larger gaps at the end of the boards when vinyl contracts in cold weather. Expansion joints are an alternative to scarf joints in such situations.

- Be sure to fasten both sides of the joint.

Fastening

Unless you are using large fasteners or installing CertaTrim in unusually low temperatures (less than 40°F), you will not need to pre-drill holes before fastening the trim.

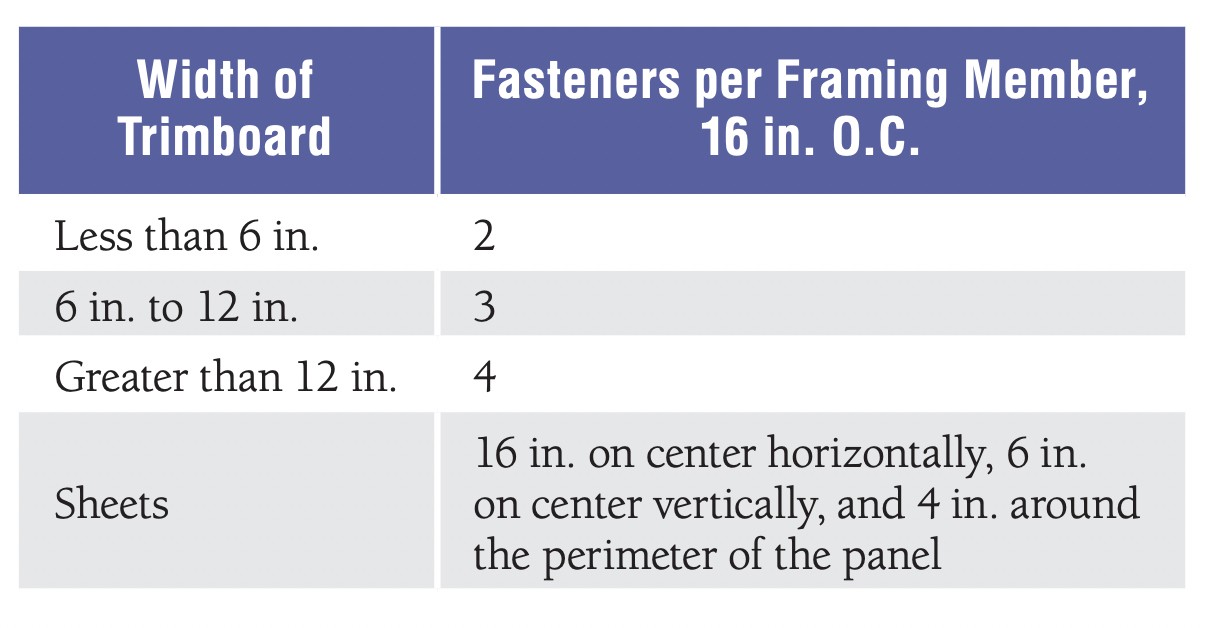

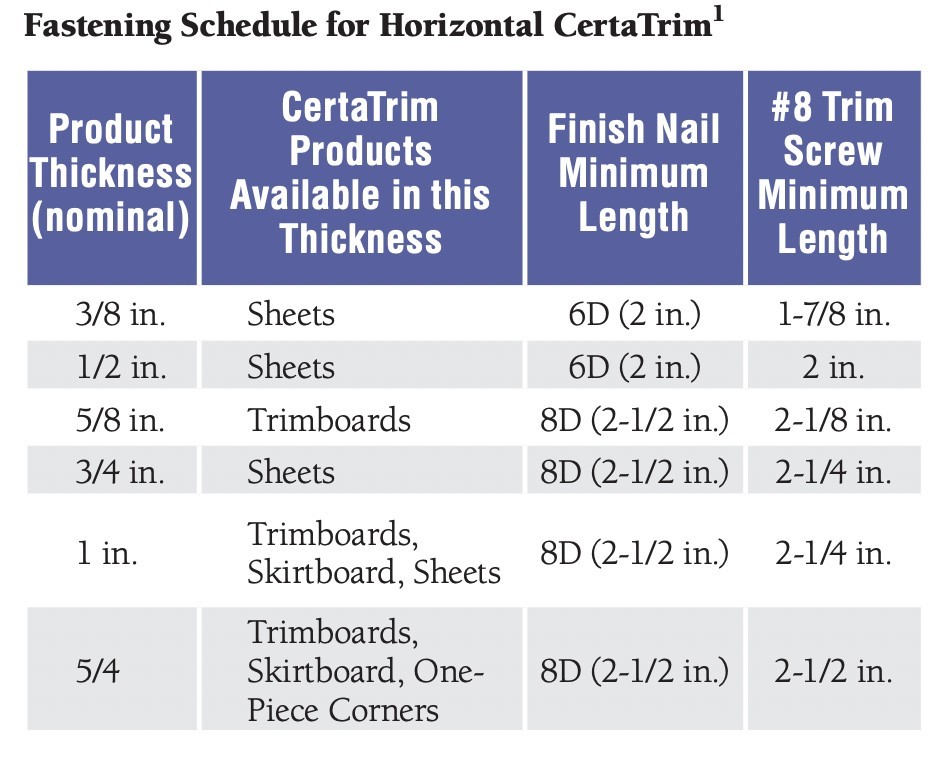

Vertical Wall Fastening Schedule

Use stainless steel or hot-dipped galvanized fasteners designed for wood trim and cladding. For best results, use fasteners with thin shanks, blunt points, and full round heads.

1 The recommended lengths and sizes assume that CertaTrim is applied over a nailable, rated structural sheathing (substrate) with a thickness of 1/2 in. applied directly to a framing member. If nonstructural sheathing is used over framing members, the fastener must penetrate through the non-structural sheathing into the framing member a minimum of 1-1/2 in.

Do not use brads, staples, wire nails, ring-shank nails, or fine-threaded wood screws.

Choose the correctly sized fastener: 1-1/2 in. of the fastener must penetrate a framing member and/or structural sheathing. If you use 1/2 in. OSB (a type of structural sheathing), the fastener needs to penetrate the framing member only 1 in. If you are covering 1/2 in. foam (non-structural sheathing), you must penetrate the framing member 1-1/2 in. In other words, in the second example, the fastener needs to be longer to meet the fastening requirements.

- Standard pneumatic nailers work well, generally at a pressure between 70 psi and 100 psi, depending upon the type of gun, the type of nail, the air temperature, and the density of the substrate.

- In-line pressure gauges will help maintain even pressure to the nail gun.

- Apply trimboards over framing no greater than 16 in. o.c. If framing members are greater than 16 in. o.c., provide additional bracing for fastening.

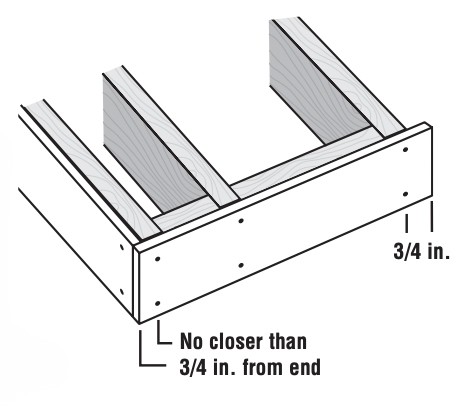

- Fastener heads should be flush with the surface of the trim or slightly indented and no closer than 3/4 in. from the end of the board to avoid blowout through the side of the board.

- Fasteners should penetrate a minimum of 1-1/2 in. through a flat, solid wood substrate into a framing member.

Note: When fastening a pocket accessory, make sure to measure 3/4 in. from the edge of the pocket. Do not fasten through the pocket. For example, to install CertaTrim with a 3/4 in. pocket, measure back 1-1/2 in.: 3/4 in. for the pocket + 3/4 in. for clearance.

Cortex® Concealed Fastening System

- The Cortex Concealed Fastening System is designed for use with CertaTrim boards with actual thicknesses of 5⁄8 in. to 5⁄4 in.

- Using the Cortex setting tool, set the Cortex fasteners perpendicular to the trim board, spaced a maximum of 16 in. O.C.

- Using a standard 18V cordless impact drill, drive the fastener to the pre-set level below the trim surface.

- Place the PVC trim plug into the hole with the trim-surface side up, and gently tap until it is flush with the trim board. To ensure a strong bond, make sure the cored hole is free of dirt or rainwater.

General Fastening Guidelines for Cortex

- For horizontal trimboards more than 12 in. wide, use 4 Cortex fasteners at every framing member, rafter tail, or wall stud.

- If the board is 6 in.–12 in. wide, use 3 Cortex fasteners.

- If the board is less than 6 in. wide, use 2 Cortex fasteners.

- Fasten within 2 in. of the end of each board. If you must fasten within 3/4 in. of the end of the board, use a 3/16 in. drill bit to pre-drill pilot holes

Touching Up Fastener Holes

Fasteners driven beyond the surface of CertaTrim boards can leave unsightly holes in the finished product. To touch up small holes in CertaTrim, we highly recommend using Extreme PVC TrimWelder. Once the product has set up, you may have to sand the area to achieve a finished appearance. When used with reasonable care, methyl ethyl ketone (MEK) also serves as an effective solvent to clean up Extreme PVC TrimWelder. You can also use caulking or glue products designed for use with cellular PVC millwork to touch up holes, but they may create less than desirable results, weather poorly, or collect dirt over time.

Bonding, Adhesives and Joinery

Gluing CertaTrim to CertaTrim or Other PVC

Use an adhesive designed for use with cellular PVC trim to bond all scarf and miter joints. To bond joints such as corners, window surrounds, and long fascia runs, we recommend TrimTight™ cellular PVC cement or Extreme PVC TrimWelder. You can also miter pieces using a Kreg Jig (www.kregtool.com). A Kreg Jig allows you to join two pieces of CertaTrim trim by drilling a hole at an angle into one piece of trim and connecting it to another with a self-tapping screw.

- Before you attempt to glue CertaTrim surfaces, make sure the surfaces are clean, dry, and in complete contact. Scarf joints work well when gluing long runs.

- PVC cement and other solvent-based adhesives have different working times, which vary from product to product. To allow sufficient time for a full cure, mechanically fasten the joint through the joint or on each side of the joint, staying 3/4 in. away from the edge of the joint.

- To ensure complete curing, make sure the glued pieces are

kept clean and adequately ventilated. This is particularly

important when bonding large panels face-to-face as

inadequate ventilation of solvents can interfere with proper

bonding.

TrimTight Glue ProTip: Always apply adhesives to both pieces of Restoration Millwork and press together to get superior bond.

Extreme PVC TrimWelder ProTip: Always apply adhesives

to one piece of Restoration Millwork and press together to get

superior bond.

Bonding to Other Surfaces

CertaTrim can also be bonded to a variety of substrates. We recommend OSI® TRIMTeQ™ TeQ Mount™ Mounting Adhesive or Loctite® PL Premium Polyurethane Construction Adhesive. Specific substrate combinations require specific adhesives: contact cement, epoxy, rubber-based adhesives, or urethane-based adhesives. Use the proper cement for each substrate. Always follow the adhesive manufacturer’s instructions, and check the bond on a test piece before proceeding with the installation. Also, be aware of the temperature and humidity, as they can affect the performance of the adhesive.

Note: Never use adhesives alone to fasten CertaTrim to a substrate.

Note: Small dents in CertaTrim can sometimes be removed using a hair dryer or heat gun. We recommend practicing on a test piece first.

Beadboard & Beadboard Panels

When installing CertaTrim Beadboard & Beadboard Panels, allow 1/8 in. for expansion and contraction at all edges and around fixed objects or abutments. Fastening Beadboard Panels

- Apply construction adhesive such as OSI® TeQ™ Mount or Loctite® PL Premium® Polyurethane Construction Adhesive to the back of the panel where it will intersect joists or contact substrate.

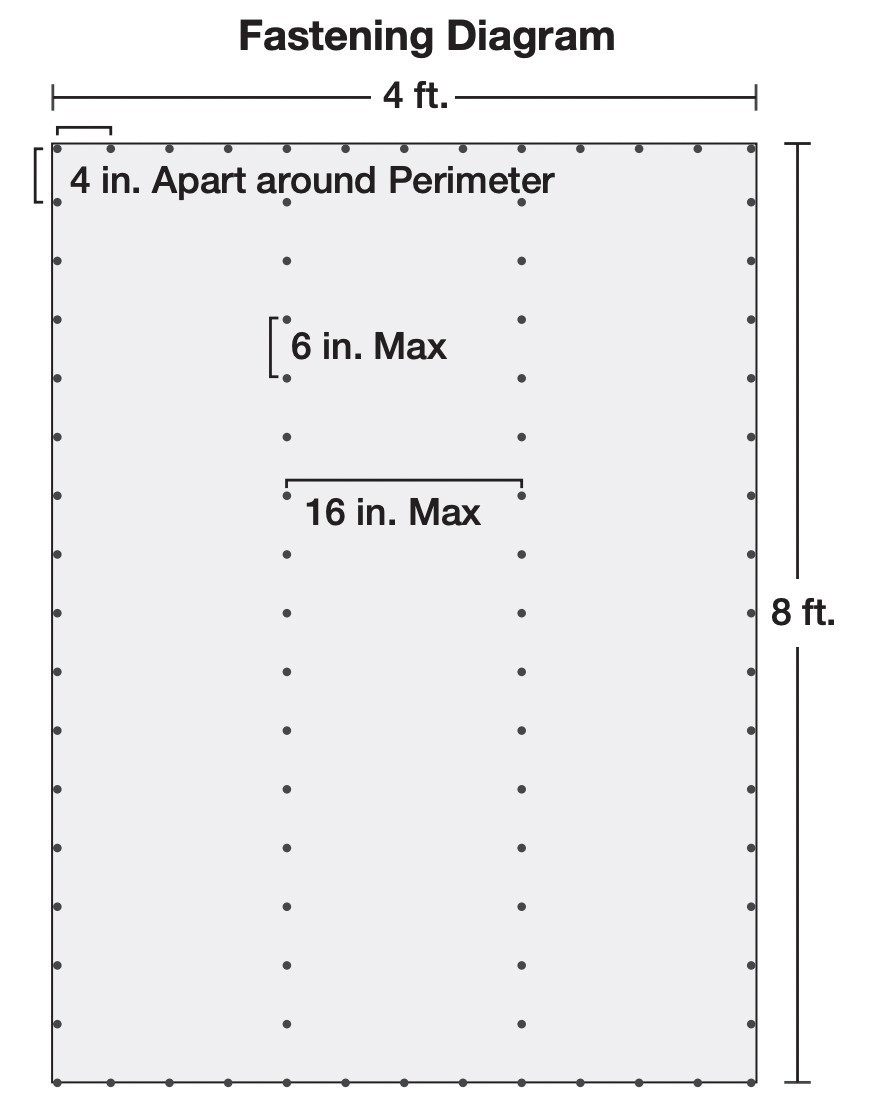

- Fasten CertaTrim Beadboard Panels to framing members, spacing fasteners no more than 6 in. apart in the field and 4 in. apart at the perimeter of the panel (see fastening diagram).

Fastening Beadboard

- Apply construction adhesive such as OSI® TeQ™ Mount or Loctite® PL Premium® Polyurethane Construction Adhesive to the back of the Beadboard where it will intersect joists or contact substrate.

- CertaTrim Beadboard should be nailed a maximum of 12 in. o.c. along its length with fasteners at least 2 in. but no closer than 3/4 in. from the end of each board.

Wainscoting Application

When installed as a wainscoting CertaTrim Beadboard and Beadboard Panels must be applied over a solid substrate. Verify that substrate is level prior to application.

Ceiling/Soffit Application

When installing CertaTrim Beadboard and Beadboard Panels in a ceiling or soffit application, verify that the area to be covered has adequate ventilation. Spanned applications such as soffit and ceilings must not exceed 16 in. O.C. Verify that framing members are level prior to application. Solid blocking must be installed where panel edges do not meet framing members to allow for proper fastener installation.

One-piece Outside Corners

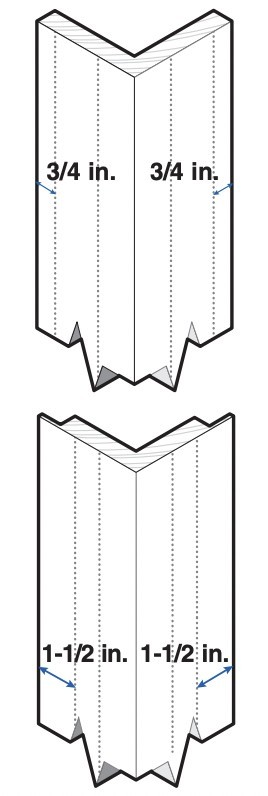

CertaTrim one-piece corners come in both smooth and Select Cedar woodgrain finish; in two width options, 3-1/2 in. and 5-1/2 in.; and with or without a built-in J-pocket. All styles are 1 in. thick, white and available in 10 ft. and 20 ft. lengths.

- Flash the corners of the structure by bending a 20 in. piece of trim coil 90° so you have two 10 in. legs. Cover the entire height of the corner, lapping the upper pieces of the flashing over the lower piece.

- Position the corner with the top of the post spaced at least 1/8 in. from the underside of the eave. The distance from the top of the post to the underside of the eave depends upon the length of the corner. Allow 1/4 in. for expansion for every 18 ft. of corner. Leave the bottom of the corner 3/4 in. below the starter strip if you will be installing vinyl siding, and trim to length.

- Make sure the post is straight and true before nailing.

- On a J-pocket corner, the pocket comes back 3/4 in. from the edge of the board. Do not nail through the J-pocket opening. Hold the fastener back 3/4 in. from the inside of the J-pocket opening. This means you will be fastening the trimboard 1-1/2 in. from the edge of the board (3/4 in. for pocket + 3/4 in. for holdback = 1-1/2 in.).

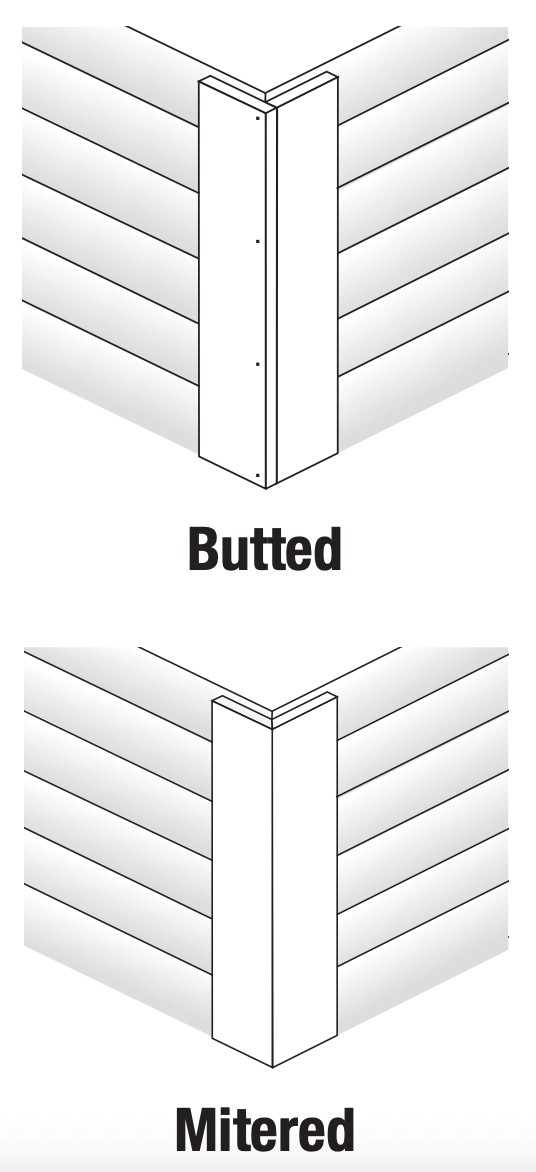

Two-piece Outside Corners

To fabricate your own corner, miter or butt the trimboards together and seal the joint with a PVC adhesive like TrimTight™ cellular PVC cement or Extreme PVC TrimWelder. PVC adhesives have a very short open time, so when gluing PVC trim, do not apply the adhesive until you are ready to bring the two pieces together.

- For butted joints, apply adhesive to the end of the trim, and fasten the corner pieces together. Use a fastener through the butt every 16 in. Let the corner cure, and install as described for one-piece corners.

- For mitered corners, assemble the corner before installing it. Cut the miter angles, apply adhesive to the length of the miter, and fasten the corner pieces together.

- Let the corner cure and install as described for one-piece corners.

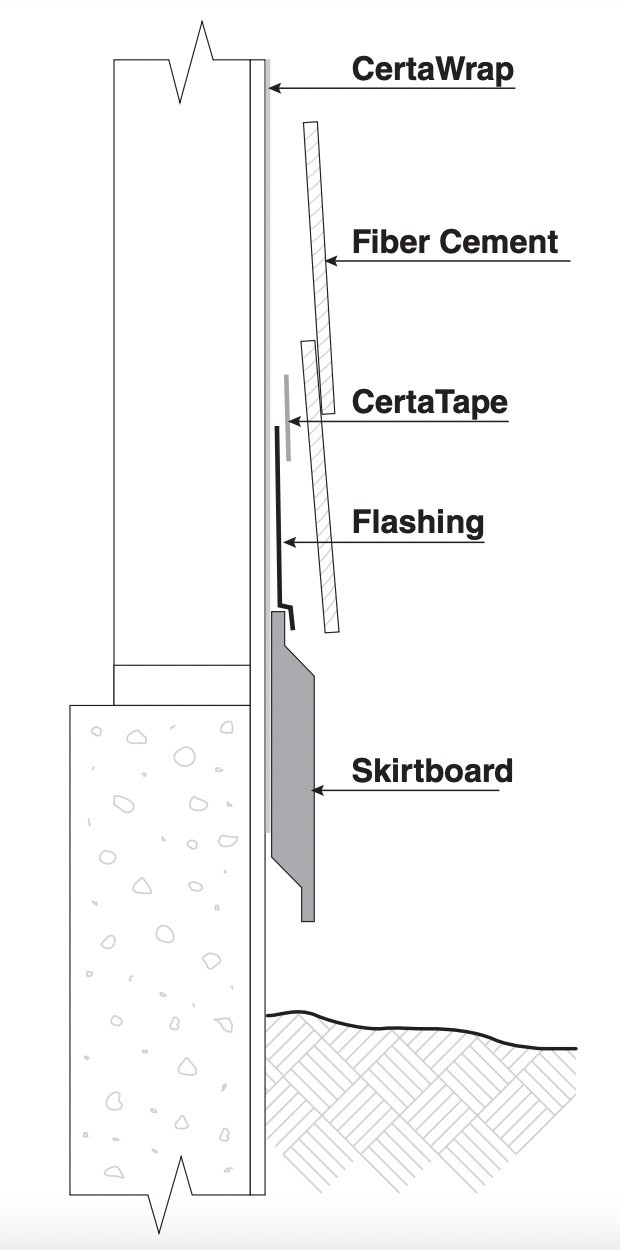

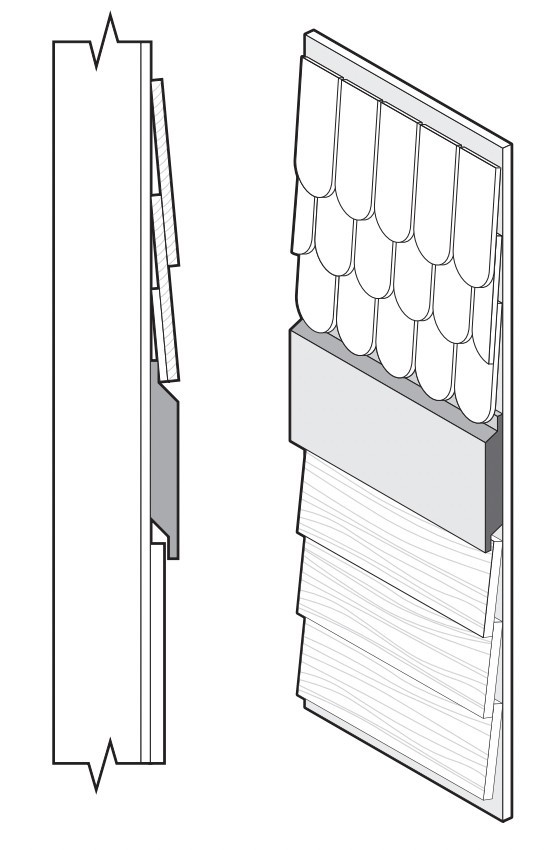

Skirtboard

CertaTrim skirtboard is used as a starting course for fiber cement siding; when transitioning from lap siding to shingle siding; and anywhere space is required below fiber cement siding—at horizontal roof-to-wall intersections, decks, and patios, or at masonry/siding transitions.

Cutting

Cut CertaTrim skirtboard with a conventional carbide-tipped wood-working blade. Do not use fine-tooth metal-cutting blades.

Expansion and Contraction

- Allow 1/4 in. per 18 ft. of product for expansion and contraction (1/8 in. at each end).

- Use 30º to 45º scarf joints to minimize seams and allow expansion and contraction.

- Glue scarf joints between the pieces to help control separation caused by expansion and contraction. Gluing the joints moves the expansion and contraction out to the ends.

- Be sure to fasten both sides of the joint.

Fastening

- Use stainless steel or hot-dipped galvanized fasteners designed for wood trim and cladding. For best results, use fasteners with thin shanks, blunt points, and full round heads.

- Standard pneumatic nailers work well, generally at a pressure between 70 psi and 100 psi, depending upon the type of gun, the type of nail, the air temperature, and the density of the substrate.

NOTE: Do not use brads, staples, wire nails, ring-shank nails,

or fine threaded wood screws.

Skirtboard must be applied over a rigid sheathing that provides a smooth, flat surface or an underlayment that is no more than 1 in. thick. Do not apply skirtboard directly to studs.

Do not install skirtboard over questionable wall construction. Irregularities in framing may become visible in the finished application. To minimize the effect of uneven walls, shim the wall as necessary

Installing Skirtboard with Fiber Cement Lap Siding

Before installing fiber cement lap siding, fasten the skirtboard the same way you would install a trimboard:

- Make sure the skirtboard is level.

- Fasteners must penetrate a minimum of 1-1/2 in. through a flat, solid wood substrate into a framing member.

- Apply skirtboard over framing no greater than 16 in. on center. If framing members are greater than 16 in. on center, provide additional bracing for fastening.

- Fastener heads should be flush with the surface of the skirtboard or slightly indented and no closer than 3/4 in. from the end or edge of the board.

- Use two fasteners per framing member for 6 in. skirtboard and three fasteners per framing member for 8 in. skirtboard.

- Position the first course of lap siding so that the bottom edge hangs a minimum of 1/4 in. over the top of the skirtboard.

- Metal flashing must be installed above the skirtboard before installation of lap siding begins. Flashing should be positioned so that it overlaps the beveled angle at the top of the skirtboard to allow water to flow out and over the board

Transitioning from Lap Siding to Shapes Siding

- Install the skirtboard so that it extends a minimum 1/4 in. over the top of the lap siding.

- Install a siding starter course.

- Align the bottom edges of the Shapes

siding and the starter course. Position

the first course of Shapes siding

so that the bottom edge hangs a

minimum of 1/4 in. over the top of

the skirtboard.

Metal flashing must be installed above the skirtboard before installation of lap siding begins. Flashing should be positioned so that it overlaps the beveled angle at the top of the skirtboard to allow water to flow out and over the board.

Window and Door Trim

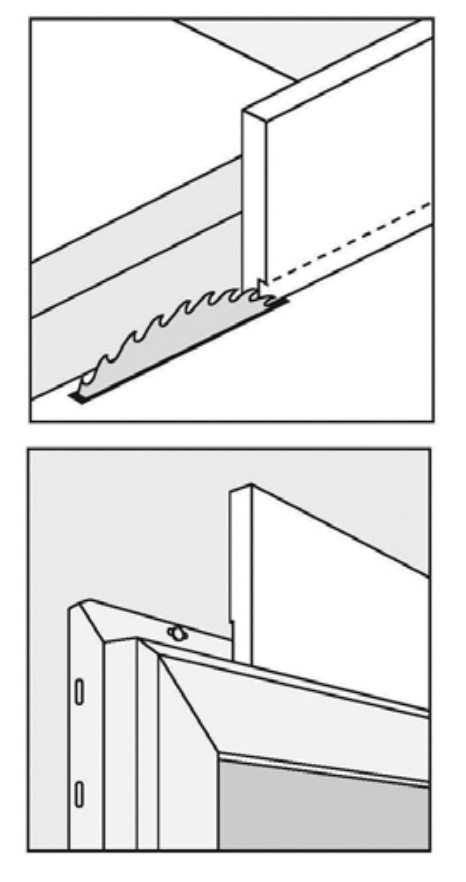

Creating a Pocket to Accommodate a Nailing Flange

Occasionally you will need to create a pocket with CertaTrim trimboards to accommodate a nailing flange in the field.

- Measure the width of the nailing flange of the window at the opening where you plan to apply trim.

- Set the blade depth of your table saw approximately 1/8 in. higher than the width of the window nailing flange.

- Set the table saw fence so you are cutting away only the thickness of the saw blade from the trimboard.

- Make one cut from the back side of the trimboard on your table saw.

- Check to be sure the trimboard will lay flat against the wall and that all joints are tight prior to fastening. If the boards do not lay flat against the wall or the joints are not tight, repeat the above instructions starting at step 3.

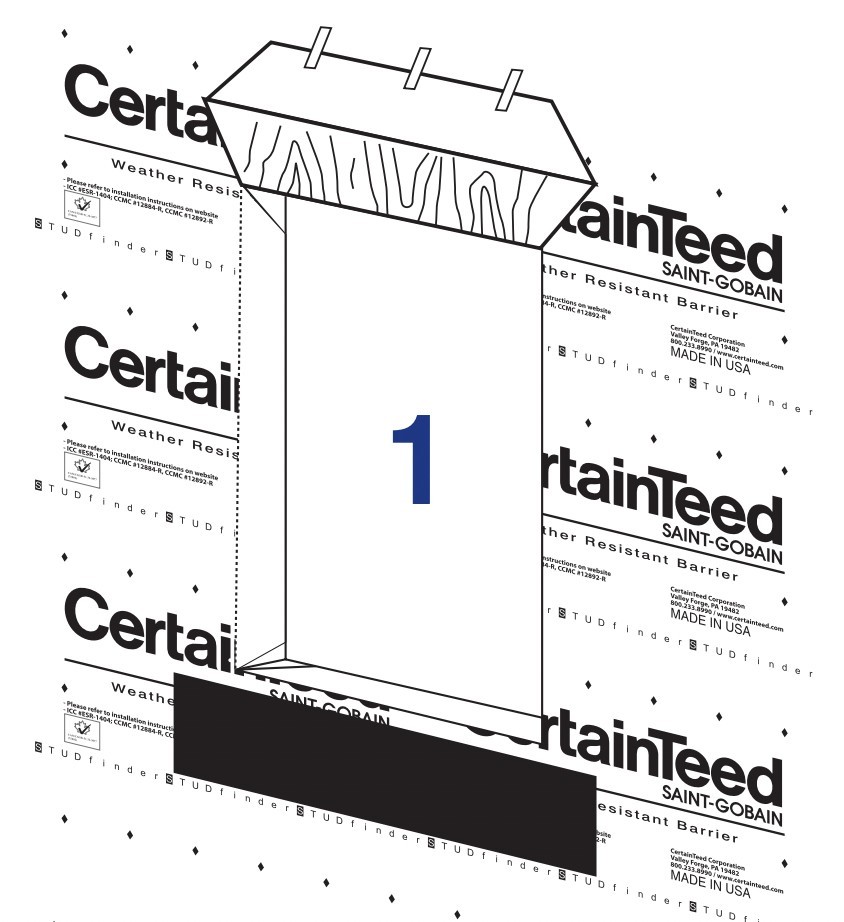

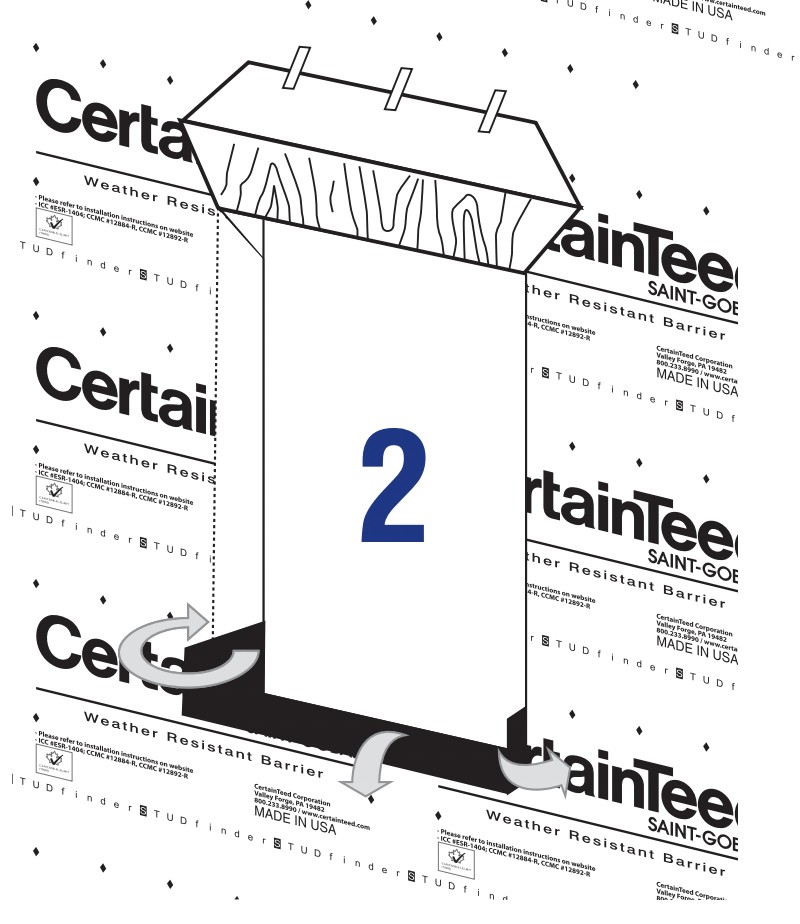

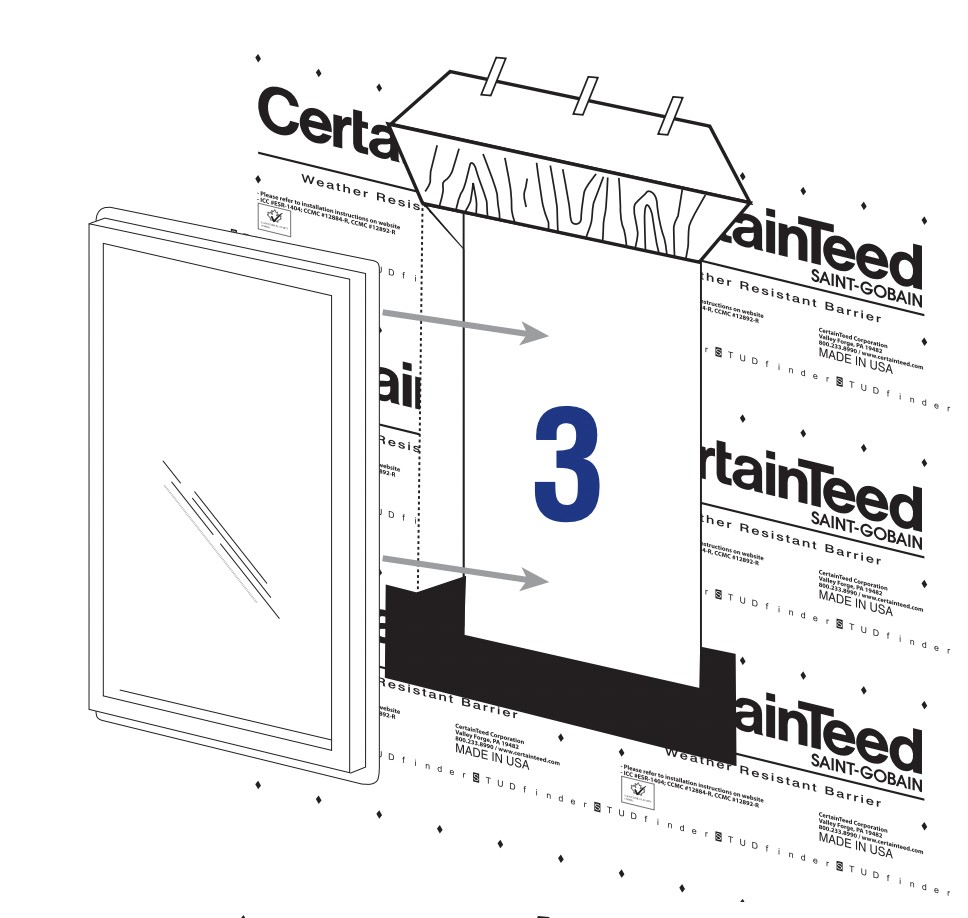

Flashing Windows and Other Openings with CertaFlash™ BA

Cladding and trim are not meant to be watertight barriers. Before you install any cladding materials or trim, flash all openings so that they shed water to the exterior of the cladding and trim materials.

To install CertaFlash around a rectangular opening:

- Make diagonal cuts in the weather-resistant barrier at the upper corners of the top (head) of the rough opening. Gently lift and tape the flap temporarily in place.

- Cut a piece of CertaFlash™ Flex flashing for the bottom (sill) that is 12 in. longer than the width of the rough opening. Remove the backer from the flashing and begin applying one end to the jamb of the rough opening 6 in. above the sill. (NOTE: the tape will extend over the exterior edge of the jamb.) Applying even pressure to the tape with your hands, work your way down the jamb, across the sill, and up the opposite jamb, finishing 6 in. above the sill. Flex the overhanging tape down onto the wall covering the weather-resistant barrier in fiber cement fashion, again applying even pressure to ensure adhesion.

- Before installing the window, apply a continuous bead of sealant to the interior of the window’s mounting flange. Install the window according to the manufacturer’s instructions.

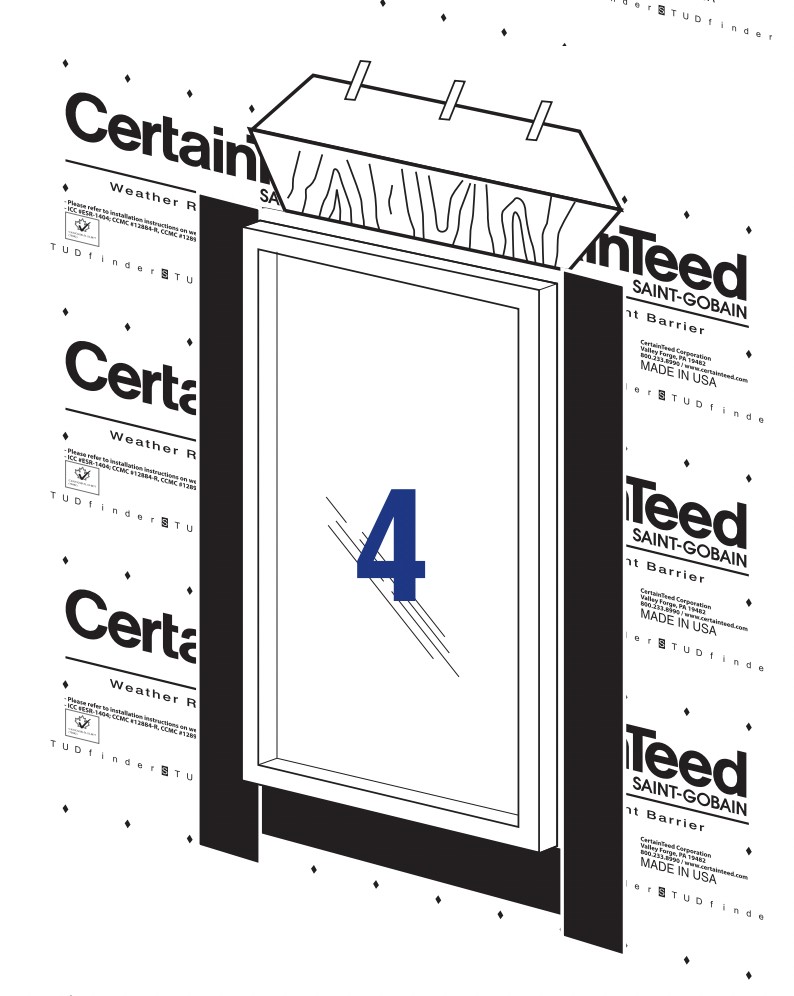

- Cut two strips of CertaFlash BA for the sides (jambs) of the window. Jamb flashing tape should extend a minimum of 3 in. above the top of the jambs of the window unit and a minimum of 1 in. beyond the bottom flashing tape installed along the sill, covering the width of the previously installed flashing at the base. Slowly peel release paper off as you press the flashing in place. Ensure the flashing covers all nails and mounting slots on the window’s mounting flange.

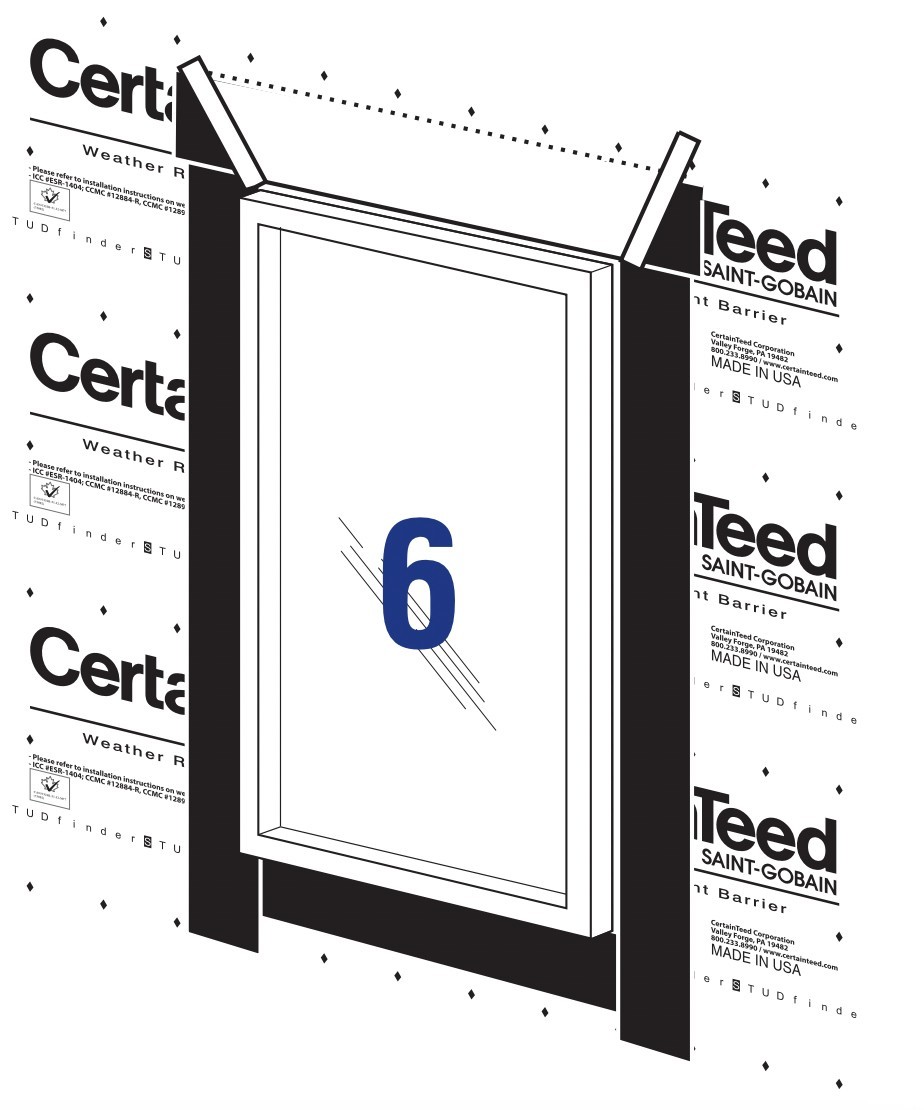

- Cut BA flashing for the top (head) of the opening so it will extend beyond both ends of the jamb flashing. Ensure the flashing covers all nails and mounting slots on the window’s mounting flange.

- Finally, lay weather-resistant barrier

over the head flashing. Apply

CertaTape over both diagonal cuts.

Rakes, Fascias and Bandboards

For best results, create a scarf joint by cutting a taper on the end of the trim pieces. Gluing the joints between the trim pieces will help eliminate separation caused by expansion and contraction. Place fasteners on both sides of the scarf joint. This will help minimize expansion and contraction.

- Allow 1/4 in. per 18 ft. of product for expansion and contraction. Allow 1/8 in. at each end of a long run.

- When you apply trim that is less than 6 in. wide, use two fasteners. For trim 6 in. to 12 in. wide, use three fasteners. Trim wider than 12 in. requires four fasteners.

- Fasteners must penetrate the substrate a minimum of 1-1/2 in.

Painting

CertaTrim comes in natural white and does not require painting for protection. If you want to paint it a custom color, follow these important guidelines:

- As with any surface to be painted, the trim must be clean and dry and free of chalk, grease, oil, dirt, or mold and mildew. To ensure good adhesion to the surface, scuff sand CertaTrim before you paint.

- To scuff sand CertaTrim trim, use 100–120 grit sandpaper or a Norton Abrasive Sponge.

- Verify that the coating manufacturer requires or approves of applying primer prior to paint application. Applying primer may reduce the drying time of the topcoat.

- For the highest quality finished appearance, use an airless sprayer to apply paint to all CertaTrim products. You can also use either a roller or brush, but a roller produces a more consistent appearance. Surfaces may be rolled then brushed to speed application, but avoid leaving some areas brushed with other areas rolled as it will affect the finished quality

- Ambient temperature, humidity, and other location-related factors can affect the drying times of coatings applied to PVC millwork. Discuss these factors with your paint distributor when choosing coating products. Good planning for jobsite conditions will lead to great results.

- Apply a 100% acrylic latex paint with an LRV (light reflective value) of 55 or higher. Generally, the higher the LRV, the lighter the color.

- For paint colors with an LRV of 55 or lower, you MUST use a paint that has been specifically developed for application on PVC. Using paint with an LRV below 55 allows the product to absorb excessive heat, which may cause PVC millwork to bow, buckle or deform. Sherwin-Williams® manufactures a line of VinylSafe™ Technology paints that are available in their SuperPaint® and Duration® lines.

- Always follow the paint manufacturer’s recommendations for the use and application of the paint.

- Due to the extended cure times of paint applied to PVC cellular trim, we recommend installing CertaTrim first and then painting it, unless the trim is painted in a professional prefinishing operation and allowed to cure completely. Sherwin-Williams provides color-match paints for PVC trim and CertainTeed vinyl siding (for details, see document CTS359, Siding & Trim VinylSafe Paint Color Guide).

CertainTeed is not liable for paint used on CertaTrim and/or the results of its use.

Bending

Convection air circulating ovens, strip heaters, and radiant heaters can be used to successfully bend CertaTrim exterior trim. These proven methods will produce a minimum amount of deformation in the shape and finish of the trim.

However, the ability to bend CertaTrim trim is limited—not all pieces can be successfully bent. For best results, do not bend any PVC cellular trim that is more than 6 in. wide.

Heat guns can also be used to bend small areas where appearance and uniformity are not critical. However, some experimentation may be necessary to perfect this “art.” Take care not to overheat the material, as overheating can produce a rough texture and discoloration.

When you bend textured cellular PVC, the wood grain will distort or disappear, depending upon the radius of the bend.

To bend CertaTrim trim:

- To guarantee uniformity, gradually increase the temperature, and heat both sides of the material simultaneously.

- In general, heating time is about 3 minutes for each 1/4 in. of thickness of material. When the trim’s shape is irregular or the heat is not uniform, heating times may be longer.

- Apply the heat evenly until the trim becomes flexible and easy to form.

Take care when handling heated materials, as hot PVC can produce severe burns. Wear protective gloves that are thick enough to avoid burns.

Cleaning

Use a soft bristle brush and a bucket of soapy water to remove normal dirt and grime. For especially stubborn stains or for mold or mildew, use a cleaner suitable for PVC products. Your local building materials retailer can supply several different brands, but test any cleaner on an inconspicuous area before you use it

From CertainTeed. Want to print a copy? Find the PDF here.