- Non-Structural Column Wraps

- Structural Fiberglass Columns

- Cellular PVC

- Decorative Millwork

- T&G | Shiplap Planks

- Premier Shutters

- Outdoor Living

- Ceiling Beams

- Flexible Mouldings

- Interior Ceilings & Walls

- Wainscoting

- Clearance Items

How To Install Recessed Panelled Wainscoting

ELITE WALL PANELED WAINSCOT – HOW-TO INSTRUCTIONS

Want to print a copy? Find a PDF here

Problem: Ordinary drywall, while commonly used in today's homes, lacks the texture and rich look of paneling used in the past.

Solution: A wainscoting treatment composed of pre-made kits that can be applied to any wall in a weekend. You can create a more interesting and unique look than you can by simply painting or applying wallpaper to drywall. Elite Trimworks provides a more upscale, formal look to any room.

If you have the tools and the know-how to install baseboards, then you have everything you need to install Elite Wall Paneled Wainscoting in any room of your home.

Note: Kits are also available for straight staircases. Flexible wainscoting kits are available for curved staircases and/or walls.

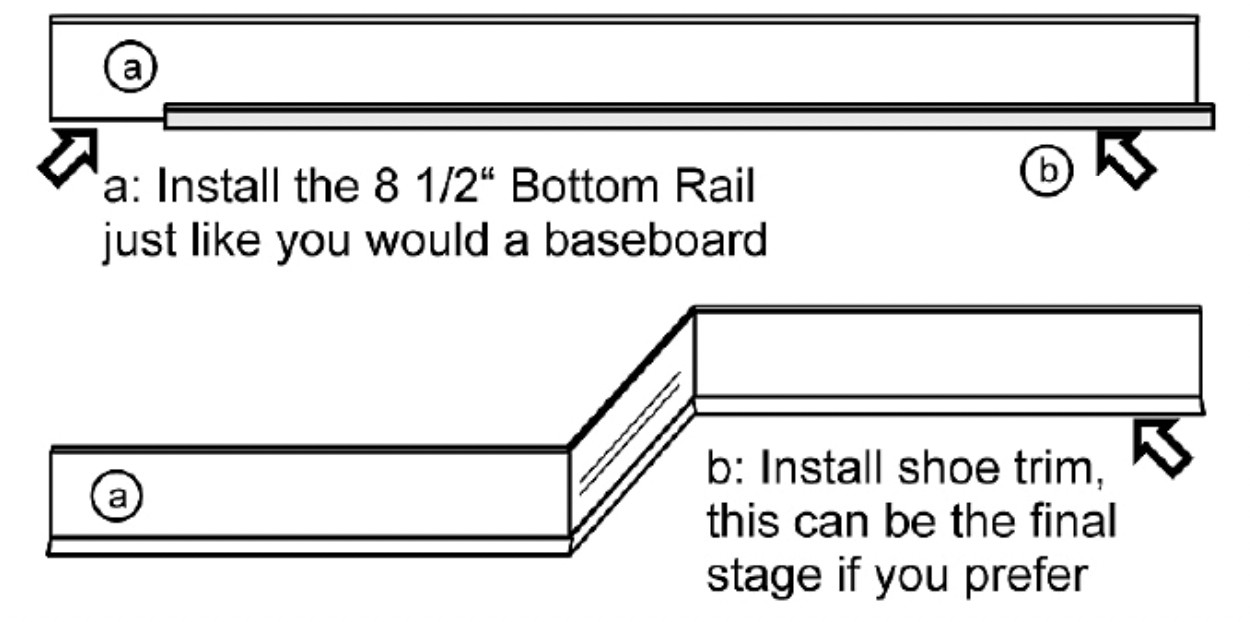

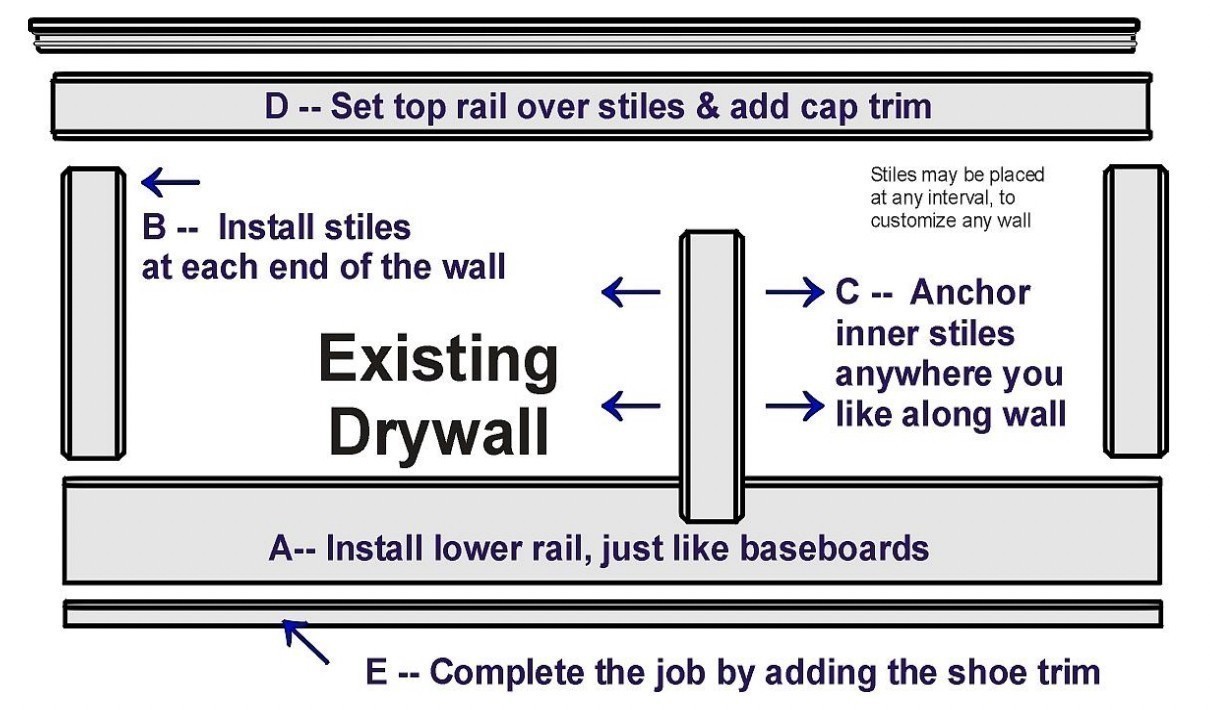

Step 1: Your room probably has baseboard moulding installed. If so remove it first. Install the 8 1/2" bottom rail just like you would any baseboard. The 1 5/8" shoe mould (used to cover imperfections or gaps in the floor) can be the next or the last step depending on the future flooring plans.

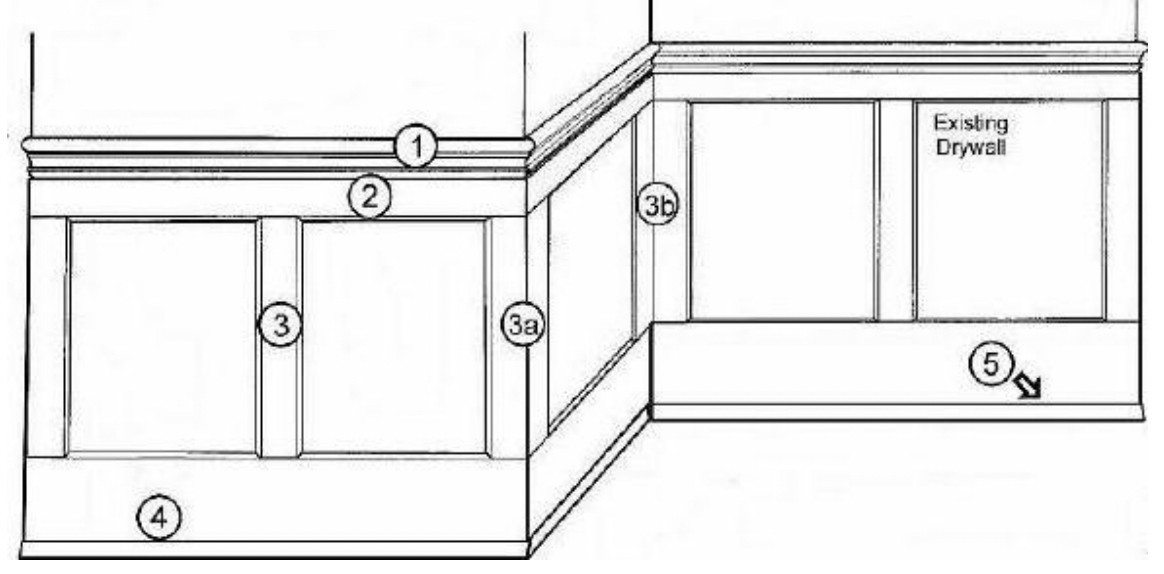

Step 2: Calculate the distance that you would like between the stiles. To start with, you will need one stile for every inside and outside corner. We Recommend 18” to 24" between stiles. Note the locations of your electrical outlets and phone jacks. Keep in mind that the panels don’t have to necessarily be the same size. Mark the stile positions with a pencil. The beauty of this product is that you will end up with symmetrical panels no matter what the wall length is. If you are short stiles, you can order them individually online.

Tip: When determining your stile locations, you may want to take the location of your electrical outlets into consideration. Decide whether it is easier to cut around the stiles, move the outlet or change the layout and distance between Stiles.

Tip: A few pointers in making corners

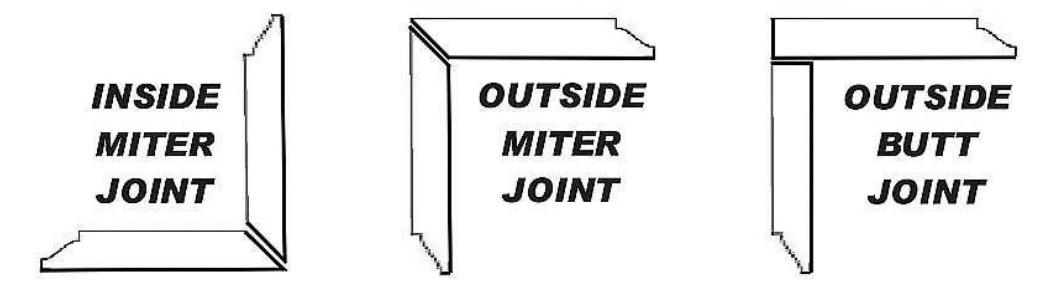

Depending on whether or not you have a table saw that will cut at a 45-degree angle, the mitered joint will give you the best results. If you don't have a saw available, a butt joint will still give you reasonable results. There are basically two types of corners, 3a - outside corner and 3b - inside corner. In either case, we recommend that you glue the joints in place with a quality construction adhesive.

The two images below show a cross-section of both methods. The big advantage of the miter joint is that it allows a greater surface area for the glue. Secondly, although it may be harder to cut, it is much easier to sand down and hide the seam completely.

The butt joint method will work just as well but allow a little more time to sand down the seam. If you still see a slight seam, don't feel bad, walls are rarely square. A little spackling or caulking is all it takes to fill these slightly larger seams.

Step 3: Make and install all inside and outside corners. Use a table saw to cut the stiles lengthwise to fit each corner. Use 45-degree cuts for corners and 90-degree cuts where the moldings will butt up against a window or door trim.

Tip: Use a quality construction adhesive on all the joints and wherever the stiles meet the Top or Bottom rail

Step 4: Now you are ready to install the top rail. Start by pinning or nailing at one end and work your way to the other corner.

Tip: If there is any play between the wall and the stiles, add a pain-table latex caulking in behind to fill in the gaps. Not only will this fill in the gap but the caulking will also act as an adhesive to help hold the wainscoting in place securely.

Step 5: Fasten the Top Rail to the wall (d) on top of the installed Stiles (b).

Step 6: Fill in the nail or pinholes with Spackling (Plaster of Paris). There should be a tight enough fit between the Stiles and the Top and Bottom Rail that it shouldn’t need finishing. Use a Paint-able Latex Caulking (DAP) wherever the wainscoting touches the wall to seal the seam between the two.

Step 7: Apply your primer coat. Elite Wall Panel Wainscoting comes pre-primed but the wall and the sanded parts of the wainscoting need a coat of primer before applying the paint type and color of your choice.

Tip: Before painting, fill in any damaged areas.

Step 8: Apply your final coat of paint. We recommend semigloss or melamine paint for easy cleaning. Wallpaper can also be used in the interior of the panels.

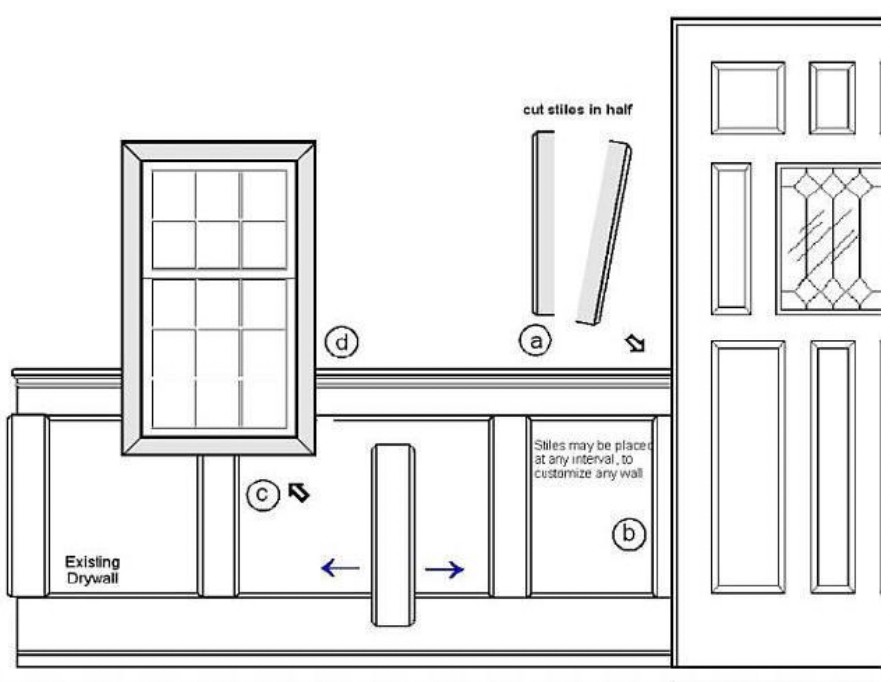

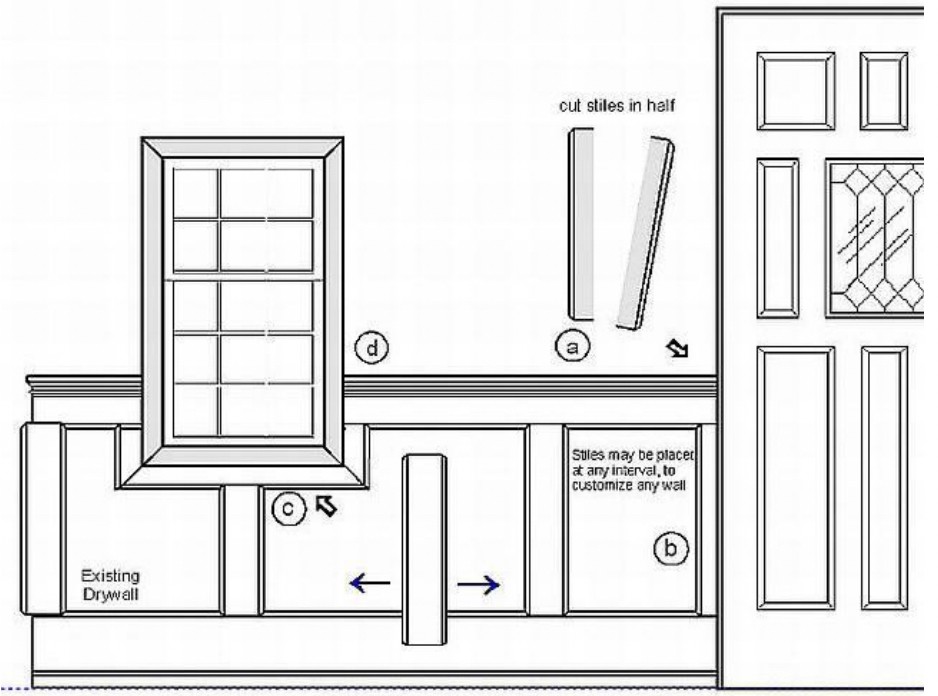

Tips on How to Trim Around Windows and Doors

1. The Simple Way: (for many people looks better) this method is great when casings are thicker than 1/2". If not, simply bevel back the wainscoting parts to equal the thickness of your existing trim. You may even consider replacing your door and window trim prior to installation.

A: A standard stile that has been cut in half at 90 degrees.

B: Place the flat side of the stile up against the door or window casing.

C: Unlike this sample, the stile does not have to go directly in the center of the window sill. Take the panel size that you would like for the entire room into consideration. The Elite Wall Paneled Wainscot kit allows you to customize the panels to suit your room and walls.

D: The Top Rail will most likely

need to be beveled back to

meet with the door trim.

2: The Double Frame Method: The major difference with this method is that you will require more components and time to trim around the window (c). Stock items can be used. Most of our customers are hobby carpenters who have more time and prefer this look. Builders, Carpenters, and Contractors are more time conscious and prefer the first method. The choice is totally up to you.

If you have any comments or suggestions, call us anytime.

Want to print a copy? Find a PDF here